Authors: Steliyan Vasilev1, Melanie Hoerr1, Michaela Kasdorf1

13E Smart Solutions, Krefeld, Germany

1. Introduction

Embroidery technology is unlocking new possibilities for the reliable and scalable integration of electronic functionality into textiles, making it an ideal solution for the production of smart textiles and wearables. This innovative approach not only enhances the durability and performance of these products but also streamlines their manufacturing process.

By leveraging embroidery, we can achieve the automated integration of discrete electrical components, such as PCBs (Printed Circuit Boards), directly into textiles. Through the precise embroidery of conductive threads, these components can be interconnected, forming complete and robust electrical circuits. In addition to connecting traces, embroidery allows for the creation of conductive areas that function as sensors or electrodes, essential for a wide range of applications.

Another key advancement in this field is the Tailored Fibre Placement (TFP) technology, which enables the precise integration of fibres, wires, or tubes into textiles. This technique offers unprecedented flexibility in design and functionality, supporting applications ranging from smart clothing to advanced medical devices.

The advantages of embroidery technology in the realm of e-textiles include:

- Reliability: Embroidery ensures high precision in the placement of components, resulting in e-textiles that are durable and maintain their functionality even after repeated washing.

- Automation: The ability to integrate and interface electronic components in a single production step significantly reduces manufacturing complexity and ensures high reproducibility.

- Scalability: Multi-head embroidery machines allow for the efficient production of e-textiles at scale, meeting the demands of both niche markets and mass production.

- Comfort: Despite the addition of electronic components, embroidered e-textiles retain their inherent textile properties, such as flexibility and breathability, ensuring user comfort.

Embroidery technology finds its application across three major areas:

- PCB Integration: Applicable across various technical fields, from consumer electronics to industrial applications.

- Textile Electrodes: Vital for diagnostics and therapy in the medical sector, as well as in wellness and fitness products.

- Tailored Placement of Fibres, Wires, and Tubes: Supports applications such as heating elements, illumination, and RFID tag antennas, expanding the functional scope of e-textiles.

2. PCB Integration

Figure 1 | A circular PCB, integrated and connected to the surrounding circuitry via embroidery

When it comes to integrating PCBs into textiles, embroidery offers a reliable and robust solution by effectively stitching the PCBs directly onto the fabric using conductive thread (Fig. 1). This method eliminates the need for adhesives or solder, which can degrade over time, especially when subjected to washing and mechanical stress.

Our extensive R&D efforts in this area have led to the development of a set of guidelines that cover both PCB design and the embroidery stitch sequence. These guidelines ensure that the connections are highly reliable, capable of withstanding significant mechanical stress and enduring multiple washing cycles without compromising functionality. This approach significantly enhances the durability and longevity of e-textiles.

Figure 2 | a) Automated LED integration with the ZSK Functional Sequin Device; b) Automated PCB integration with the ZSK PCB Placement Device.

To further streamline the PCB integration process, ZSK has developed two specialized devices designed to automate the embroidery of electronic components onto textiles.

- ZSK Functional Sequin Device

This innovative device enables the automatic integration of small flex PCBs with surface-mounted components (SMDs) into textiles (Fig. 2a). These components can include LEDs, temperature sensors, transistors, RFID chips, and a wide range of other electronic elements. By automating this process, the ZSK Functional Sequin Device ensures consistent placement and connection, enhancing both efficiency and reliability in production.

- ZSK PCB Placement Device

The ZSK PCB Placement Device is designed to place, fix, and connect PCBs to textiles in a single production step (Fig. 2b). The first generation of this device was specifically developed for rigid PCBs, ensuring precise placement and strong connections. Currently, the second-generation device is in its final stages of development, expanding its capabilities to include the placement of flexible PCBs as well. This evolution in technology transforms the embroidery machine into a versatile pick-and-place system, where interconnections are established concurrently with PCB placement.

Both of these devices exemplify the synergy between automation and reliability, enabling the efficient production of complex e-textiles with integrated electronic functionality.

3. Textile (Moss-Embroidered) Electrodes

Figure 3 | Moss-embroidered electrodes can be integrated into close-fitting clothing for vital signs monitoring.

The second major application area of embroidery technology in e-textiles is the production of textile electrodes, also known as “moss-embroidered electrodes.” This name stems from the distinctive 3D structure of the embroidery, which resembles the texture of moss (Fig. 3). In traditional embroidery, this technique is often referred to as Chenille embroidery.

The 3D structure of moss-embroidered electrodes offers significant advantages in terms of functionality. When these electrodes are applied to the skin, the large surface area created by the raised, textured embroidery ensures a substantial contact area. This extensive contact results in a very low electrode-skin impedance, which is crucial for accurate and reliable signal transmission.

This characteristic makes moss-embroidered electrodes particularly effective in a range of applications. In the medical field, they can be used for diagnostics, monitoring, and therapeutic devices, where precise bio-signal acquisition is essential. Additionally, their comfort and effectiveness have expanded their use into the wellness and fitness industries, where they are integrated into products such as smart clothing, wearable fitness monitors, and recovery gear.

The versatility of moss-embroidered electrodes demonstrates the potential of embroidery technology to create functional, high-performance components that maintain the comfort and flexibility of traditional textiles.

4. Tailored Placement of Fibres/Wires/Tubes

The third major application area of embroidery technology is the precise and tailored placement of fibres, wires, and tubes within textiles. This capability opens up a wide range of functionalities, allowing textiles to go beyond their traditional roles and serve as smart, interactive components in various products.

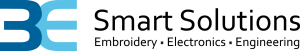

Figure 4 | a) Integration of heating fibre using ZSK’s W-head; b) Thermal image of embroidered conductive fibre; c) Embroidered heating element integrated into a dog coat.

One of the most common applications of this technology is heating (Fig. 4). For instance, embroidered heating elements are widely used in car seats, ensuring high reliability and durability. Beyond automotive applications, heating elements are also integrated into medical and wellness products, such as therapeutic heating pads, as well as into heated garments like jackets and gloves designed for extreme weather conditions. The ability to precisely place heating wires within these textiles ensures even distribution of heat, improving the effectiveness and safety of these products.

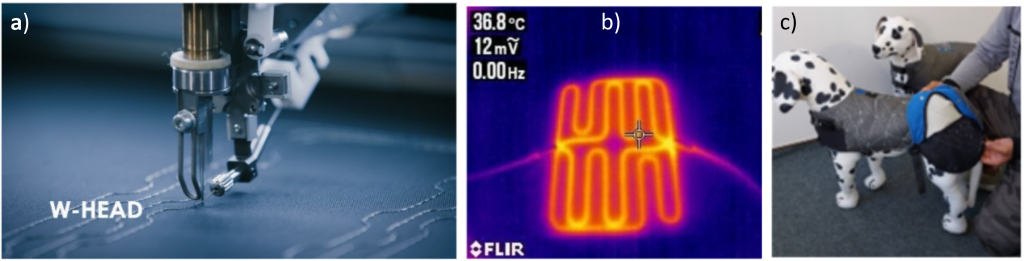

Figure 5 | a) Plastic optical fibres integrated into textile with ZSK’s W-head; b) Dog coat with integrated illumination.

Another exciting functionality made possible through embroidery is illumination (Fig. 5). By integrating optical fibres or specialized LED wires into textiles, it is possible to create illuminated surfaces that serve both functional and aesthetic purposes. For example, illuminated textiles can enhance visibility and safety in protective clothing or be used as a decorative element in fashion, adding a unique visual effect to garments and accessories.

In addition to heating and illumination, embroidery technology allows for the creation and integration of sensors. The resulting smart textiles can be used in a wide range of applications, from monitoring structural health in buildings to enhancing the functionality of wearable devices that track body movements or postures.

The tailored placement of fibres, wires, and tubes through embroidery technology not only enhances the functionality of textiles but also ensures that these enhancements are automatically integrated, maintaining the flexibility, breathability, and comfort of the original fabric.

5. ZSK Embroidery Machines for E-Textiles

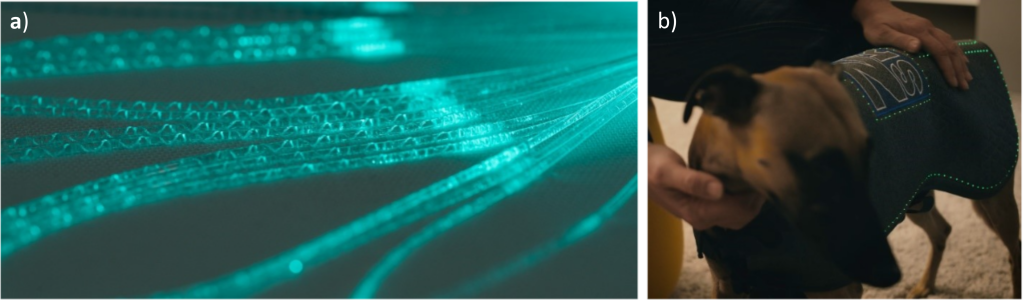

Smart textiles can generally be produced using any ZSK embroidery machine, thanks to their versatility and precision. However, certain e-textile applications require specific embroidery heads or additional attachments to achieve optimal results. Table 1 provides a comprehensive overview of the most popular e-textile applications and the corresponding embroidery heads and attachments necessary for their production.

Table 1 | Overview of popular e-textiles applications and corresponding embroidery equipment necessary for their production.

Fig. 6 showcases the ZSK JGVA 0109 embroidery machine, which is equipped with all three essential embroidery heads. This machine, in combination with the appropriate attachments, is capable of producing the full spectrum of e-textile applications, from heating elements to moss-embroidered electrodes and integrated PCBs. The ZSK JGVA 0109 is therefore an ideal choice for companies and universities involved in the development and innovation of smart textiles and wearables, offering a single platform for a wide range of applications.

Figure 6 | ZSK JGVA 0109-500(700) embroidery machine. Move the cursor to the yellow points for info.

Get In Touch

If you’re curious about the e-textile applications possible with ZSK embroidery machines, we invite you to reach out to us using our contact form or email us at info@3esmartsolutions.de. Our experts are available for a free consultation to help you explore the full potential of this technology. We guide you from the initial idea through product development to the selection of the right equipment for your specific needs.