3E Smart Solutions

Figure 1 | 3E Embroidered Piano – interactive smart textiles demonstrator – available here

Smart textiles are often surrounded by myths that make them seem complicated, costly, or out of reach for “normal” embroidery businesses. Many companies assume they would need new machines, special knowledge, or even an entirely new business model to get started.

The reality is much simpler. If you already work with ZSK industrial embroidery machines, you are closer to smart textiles than you think. It’s not about replacing what you do today — it’s about extending embroidery with new functionality. From heating and sensing to illumination and electrodes, the possibilities are broad, and the first steps are easier than most expect.

In this article, we address three of the most common myths — plus a bonus myth about washability — and show you the reality behind them.

Myth 1: “Smart Textiles Are Difficult to Start With”

When people first hear the term smart textiles, they often imagine something futuristic, expensive, and reserved for high-tech companies or research labs. The reality is much simpler. If your company already runs ZSK industrial embroidery machines, you already have the tools you need to take the first step into this growing market.

The Reality: Starting is often harder than doing

Like with many things in business, the biggest hurdle is getting started, not the work itself. Smart textiles don’t require you to reinvent embroidery — they are simply an extension of what you already do well.

For example, one of the simplest ways to begin is by using conductive embroidery thread instead of your regular thread. That’s it. You run your ZSK machine just as you normally would, but the result is no longer just decoration — it’s also functional. Suddenly, your embroidery can carry current, connect components, or form the foundation for sensors or heating elements.

It’s a surprisingly small change that opens up a world of new opportunities.

Why this matters for your business

The move into smart textiles isn’t just about adding technology for technology’s sake — it’s about gaining new business opportunities:

-

New markets: Expand from classic embroidery into wearables, heated garments, wellness products, automotive interiors, and even pet accessories.

-

Premium services: Offer your existing customers added functionality alongside decoration — and command higher margins.

-

Faster innovation: Create small functional samples that impress clients and speed up decision-making.

-

Future readiness: Position your company as an innovator, not just a supplier.

Smart textiles don’t have to feel overwhelming. With your current machines, it can be as simple as swapping the thread.

A Hands-On Way to Start: The Piano DIY Kit

Want a simple, practical way to experience smart textiles? Our DIY Kit allows you to easily recreate the popular embroidered piano demonstrator. It’s an engaging project that shows your team how embroidery can go beyond decoration — turning stitches into real functionality.

Follow along with our step-by-step tutorial and see how quickly results appear:

Get your DIY Kit today and build confidence by creating your own functional sample.

Myth 2: “You Need Costly, Special Equipment to Make Smart Textiles”

A common hesitation we hear from embroidery companies is: “We’d love to try smart textiles, but we can’t afford to invest in new machines or special setups.”

The truth? You don’t need costly, special equipment to get started.

If you already own ZSK industrial embroidery machines, including the SPRINT series, you’re equipped to enter the smart textiles market. Your current heads and workflows are capable of much more than decoration — they can create functional textiles that customers in fashion, sports, wellness, automotive, and healthcare are already demanding.

The Reality: Your machines can already do more

ZSK embroidery technology is designed with flexibility in mind. Here’s what your existing equipment can achieve:

F-Head

-

Embroider conductive traces (and cover them with non-conductive thread)

-

Connect to PCBs and connectors

-

Create conductive areas for sensors

-

Integrate thin, flexible wires – contact us to learn how

Optional F-Head Attachments

-

Functional Sequin Device (FSD): place flexible PCBs with LEDs or ICs

-

PCB Placement Device: integrate larger PCBs automatically

-

Cording Device: process fibers and highly flexible wires

K-Head

-

Chenille or moss embroidery — ideal for soft textile electrodes used in wellness, sports, or medical products

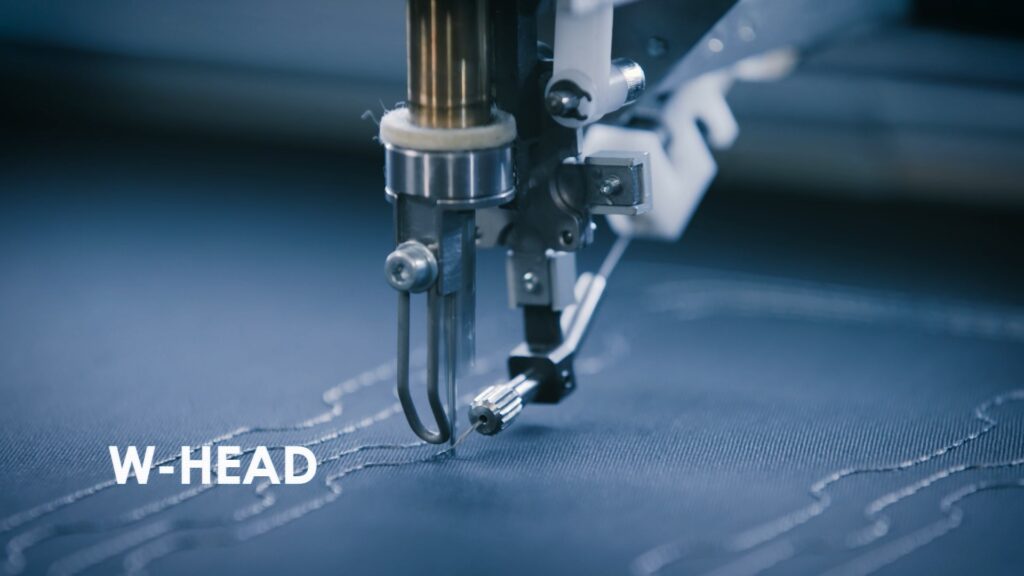

W-Head

-

Tailored placement of wires, fibers, and tubes for applications such as heating, illumination, RFID antennas, and sensors

-

Greater material flexibility compared to the Cording Device

Why this matters for your business

-

Low entry barrier: You don’t need a new setup to begin — your current machines already open the door.

-

Stepwise investment: Add attachments later when customer demand grows.

-

Fast ROI: Start small, deliver new functional samples, and win projects without large upfront costs.

-

Future-proofing: Offer both decoration and function, positioning your company as a solution provider, not just a supplier.

Unsure what your setup can do?

We can analyze your ZSK setup and map out exactly what applications you can start with today — and what simple add-ons could extend your range further.

Myth 3: “Smart Textiles Are a Completely Different Business”

When many embroidery companies hear about smart textiles, they imagine that moving into this field would mean reinventing their entire business. New skills, new workflows, new customers — it sounds like a completely separate world.

The truth is: smart textiles are not a different business — they are an extension of embroidery.

The Reality: It’s still embroidery, just with function added

The stitches, machines, and workflows remain familiar. Your operators won’t have to start from zero. The only difference is that your embroidery doesn’t just decorate — it also adds functionality.

From your team’s perspective, the process still feels like embroidery. From your customer’s perspective, the result transforms into something unique, valuable, and innovative.

Think of it as giving embroidery a new dimension.

Why this matters for your business

Leverage existing skills: Your staff already knows how to run the machines — smart textiles use the same embroidery logic.

Short learning curve: Teams can create functional samples in as little as a day, especially with targeted training.

Upsell opportunities: Turn decorative logos into illuminated branding, simple stitches into heating elements, or soft patches into electrodes.

Stronger customer relationships: Once clients see that you can deliver both branding and function, they’ll turn to you for more projects.

Positioning as an innovator: Without changing your core business, you showcase yourself as forward-looking and capable of handling new markets.

How ZSK and 3E support you

To help you bridge the gap from “classic embroidery” to smart textiles, we offer tailored trainings and workshops that cover:

-

Digitizing software for functional designs

-

Embroidery process specifics for conductive threads, wires, and special materials

-

Application-focused modules for heating, sensing, illumination, and more

These sessions are designed for your team, your machines, and your applications — so the knowledge transfers directly into your production environment.

Bonus Myth: “Smart Textiles Can’t Survive Washing”

Figure 2 | A waterproof sample with three LED sequins soaked in water; embroidered with the ZSK F-head and Functional Sequin Device – watch video

One of the most persistent concerns about smart textiles is washability. After all, textiles are meant to be worn, handled, and cleaned. The assumption is that adding functionality makes them fragile or unsuitable for everyday use.

The truth is very different: with the right design and protection, embroidered smart textiles are reliable, durable, and can withstand many wash cycles.

The Reality: Washability is part of the design

Embroidery is inherently robust — stitches are made to flex, bend, and last. This durability also applies to embroidered conductive paths and functional structures.

-

Protection is possible: Conductive threads and components can be insulated or laminated so that water and detergent do not affect performance.

-

Proven in tests: In our lab, embroidered connections continued to function even after dozens of machine wash cycles.

-

Custom per product: Washability should always be tested for the specific product design, materials, and washing conditions — but the technology itself is not a barrier.

Washability is not a hurdle to overcome — it is simply another aspect of good product design.

Why this matters for your business

-

Customer confidence: Being able to say “washable and reliable” removes one of the biggest objections to smart textiles.

-

Market readiness: Products for sports, wellness, and medical applications must endure washing — embroidery technology can deliver that.

-

Competitive advantage: While others worry about durability, you can show tested results and move faster toward commercialization.

Talk to Us About Designing for Durability

Smart textiles are not fragile experiments. With embroidery, they can be as durable and washable as traditional textiles — giving your customers confidence and your company a clear competitive edge.

Smart textiles are not a futuristic dream — they are a practical opportunity for embroidery businesses today. By starting with small steps, such as using conductive thread or exploring simple functional applications, you can impress customers, expand into new markets, and increase margins without major changes to your existing setup.

The myths we’ve discussed often hold companies back. But the reality is clear: with ZSK embroidery technology and the right guidance, smart textiles are reliable, scalable, and profitable.

Now is the right time to explore what embroidery can do beyond decoration.